Your agreement to comply with and be bound by these Terms and Conditions is deemed to occur upon your first use of the Web Site. This agreement applies as between you, the User of this Web Site or Purchaser and Parmley Graham Limited the owner(s) of this Web Site. This enables operators to quickly generate toolpaths and profiles for programming directly from CAD files.All goods supplied by us are sold upon the following conditions. Thanks to SINUMERIK Operate, ShopMill and ShopTurn programming now have the option of DXF import for profile generation. The increased red area shows more consistent velocity, resulting in improved surface finish. The Advanced Surface setting can also be applied simply by activating CYCLE832 in program. The smooth acceleration and braking of the machine tool axis also helps to extend the service life of the machine. In turn, this maximises machine velocity and improves control to intelligently reduce jerk – ideal for die and mould manufacturers. It is an intelligent motion control function that uses the advanced predicative capability of the Siemens control, combined with the optimised compressor functions, to smooth toolpaths. Mazak Siemens machines all benefit from a range of surface finish improvement options available as part of CYCLE832 Advanced Surface setting. Machine kinematics can be easily reset by customers which require exceptionally high tolerances on parts.ĬYCLE832 – Advanced Surface CYCLE832 – Advanced Surface Kinematics can be calculated and set in the machine using a probing cycle which is supplied as standard. Kinematics are the machine’s parametrisation of the measured position and centre of rotations for all axes. Mazak has also developed OEM customisation of the Siemens standard CYCLE996 to accurately set the kinematics of the Mazak machines. The powerful TRAORI function can be easily programmed and set-up on Mazak machines fitted with Siemens 840D controls. During machining, the Siemens control adjusts the rotary and linear axes of the machine, instantly aligning the workpiece normal to the cutting tool’s rotational axis, while taking the kinematics of the machine and the tool length into consideration.

TRAORI (Tool Tip Tracking or Tool Centre point Control) is a DYNAMIC process used in 5-axis machining. This allows rapid programing and exceptionally fast set-up of 3+2 parts on the machine control. The machine will then automatically position the workpiece (if requested), presenting it in the correct direction to the cutting tool axis. CYCLE800 converts the active workpiece zero to a rotated surface, taking into account the kinematics of the machine. The Swivel cycle CYCLE800, which can be called in ShopMill, G-code programming, or directly from the control panel, is a powerful yet simple function that allows an operator to define a rotated working plane.

3 + 2 axis programs can be generated very quickly. Siemens controls make the programming of complex multi sided parts very simple. CYCLE800 / SWIVEL CYCLE – 5-axis Positioning Parts Made Easy CYCLE800 / SWIVEL CYCLE – 5-axis Positioning Parts Made Easy

#Shopturn software software

Mazak’s Siemens Product Group regularly works with CAM software houses to optimise post processors and templates. As the Siemens control is an industry standard control, many well-known CAM systems have pre-defined post processors that will generate accurate G-code for Siemens with minimal post processor work.

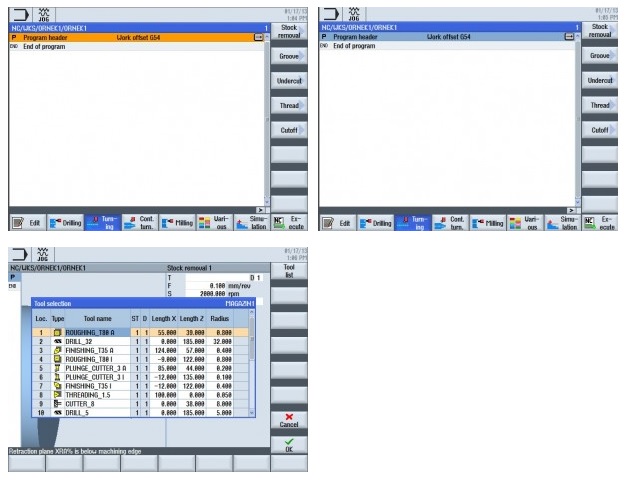

#Shopturn software full

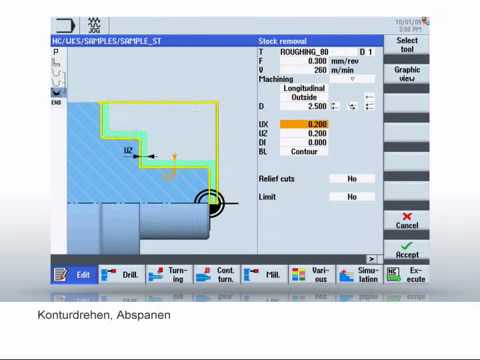

The control also facilitates the 3D simulation and swift programming of material removal strategies, measurement, swivel cycles and tool optimisation.įor intermediate program creation, G-code Cycle Support allows the full flexibility of an ISO G-code program to be accompanied with graphical animations which describe the cycle’s options.Īs with all modern CNC machine tool controls, the more complex programs are posted from CAM system in G-code programs. Even more complex 3+2 axis programs can be quickly put together using an array of clever pre-defined cycles and strategies.

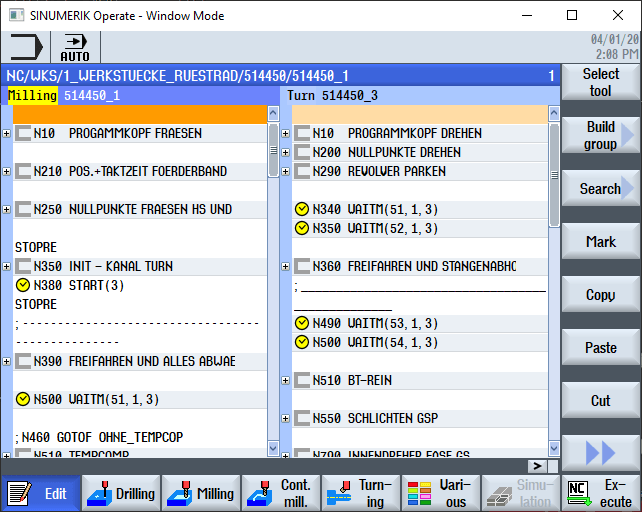

Each program step is supported with graphical animations that act as a detailed guide through the programming options. SINUMERIK Operate, ShopMill and ShopTurn are exceptionally fast and intuitive for programming. While still supporting standard G-code and DIN/ISO programs, there is also the option for machine operators to use ShopMill or ShopTurn, which is the Siemens conversational programming language. Mazak Siemens machines benefit from a number of advanced CNC programming options. ShopMill / ShopTurn / Cycle Support ShopMill / ShopTurn / Cycle Support

0 kommentar(er)

0 kommentar(er)